What Is Static Pressure in Ductwork and Why It Matters

- Dec 23, 2025

- 13 min read

In the simplest terms, static pressure is the measurement of resistance your HVAC system's air faces as it moves through your ductwork. A great way to visualize this is to think of an inflated balloon. That outward push the air exerts on the balloon's skin? That's a perfect analogy for static pressure.

Inside your HVAC system, it's the force the air pushes against the duct walls while it's waiting to move out through your vents.

The Hidden Force Inside Your HVAC System

Picture your HVAC system's blower as its lungs and the network of ducts as its airways. For your house to "breathe" correctly, that air has to flow without restriction. Static pressure is basically the amount of effort it takes to push that air through the entire system.

Every single component adds a little bit of resistance. The air filter, the evaporator coils, dampers, and even the simple twists and turns in the ducts themselves create obstacles. When this total resistance gets too high, your system has to work way harder; it's like trying to breathe through a skinny coffee straw.

Why It's a Critical Health Metric for Your HVAC

Getting a handle on static pressure is absolutely vital because it has a direct line to your system's performance, how much energy it uses, and how long it lasts. An unbalanced system fighting against high static pressure is a recipe for trouble, leading to a few common problems:

Reduced Comfort: You might notice certain rooms feel stuffy or that the airflow trickling from the vents is disappointingly weak.

Higher Energy Bills: The blower motor has to go into overdrive, sucking down more electricity just to shove air through the constricted ductwork.

Increased Wear and Tear: This constant strain can cause expensive parts like the fan motor or even the compressor to fail much sooner than they should.

Industry data gathered over 25 years paints a pretty stark picture. The average residential HVAC system operates at a static pressure that, if compared to human blood pressure, would be like a reading of 200 over 133, a far cry from the healthy 120 over 80 standard. This shows just how much stress most home systems are really under. For a deeper dive, you can learn more about how professionals pinpoint duct deficiencies on the HVAC blog from ACCA.

This invisible force is very often the real culprit behind common HVAC complaints. Obstructions inside the ducts, like a heavy buildup of debris, are a huge contributor to the problem. To get a better idea of what might be creating that resistance, check out our guide on what's inside your air ducts. Keeping this pressure in check is truly the key to a healthier, more efficient home comfort system.

Understanding How Air Moves Through Your Ducts

To really get a handle on what static pressure is, it helps to think of it as one half of a powerful duo. The air moving through your HVAC system is pushed and pulled by two different kinds of pressure working together: static pressure and velocity pressure. These two forces combine to get conditioned air where it needs to go in your home.

Think about a simple garden hose with the nozzle twisted shut. The water inside isn't moving, but it’s pushing outward on the walls of the hose, full of pent-up energy. That outward force is just like static pressure.

Now, squeeze the handle. The water shoots out with speed and direction. That forward-moving energy is the velocity pressure. Your ductwork is playing by the same rules, just with air instead of water.

The Two Forces of Airflow

Inside your ducts, the blower fan shoves air into the system, creating pressure that pushes outward in all directions. That’s your static pressure. At the very same time, that air is being propelled forward, down the duct runs and toward your rooms: that’s the velocity pressure. These two are in a constant dance, balancing each other out as air snakes through the twists and turns of your duct system.

The relationship between static and velocity pressure is a constant give-and-take. When ducts get narrower, air has to speed up, which increases velocity pressure and causes static pressure to drop. When ducts widen out, the air slows down, decreasing velocity pressure and allowing static pressure to build back up.

Getting this balance right is absolutely critical for an efficient system. When the pressures are properly balanced, every room gets the right amount of airflow, which is the key to consistent temperatures and good indoor air quality. If you're interested in air quality, our guide on how to calculate air changes per hour dives into a related concept for keeping your home’s environment healthy.

The sum of both forces is what we call total pressure. You can think of it as the total energy your system has to move air from the furnace or AC all the way to the vents in your living room. When static pressure gets too high because of a blockage, it literally chokes off the velocity pressure, leaving you with that weak, ineffective airflow that makes some rooms feel stuffy and uncomfortable.

How Professionals Measure Static Pressure

Knowing you might have a static pressure problem is the first step, but how does a technician actually put a number to it? They can’t just guess; getting an accurate diagnosis for your system requires precise data. Measuring static pressure is a fundamental part of any real HVAC assessment, and it involves a specific tool and a very particular unit of measurement.

The go-to tool for this job is a manometer. This device is the gold standard for HVAC diagnostics because it's designed to measure tiny differences in pressure. A technician uses it to read the pressure inside your ductwork and compare it to the air pressure outside of it, giving them a clear picture of the resistance your blower fan is fighting against.

This pressure isn't measured in pounds per square inch (PSI) like you'd see for a car tire. The HVAC world uses a much more sensitive unit called inches of water column, usually shortened to in. WC or "w.c.". This unit literally represents the amount of pressure needed to lift a column of water by one inch, which makes it perfect for the low-pressure world inside your ducts.

Translating the Numbers: What Do They Mean?

That reading from the manometer tells a skilled technician just about everything they need to know about your system's health. While every furnace and air handler is a bit different, most residential HVAC units are designed to run at their peak efficiency at or below a total external static pressure of 0.5 in. WC.

Think of this as the sweet spot. When the reading starts climbing much higher than that, it's a huge red flag that airflow is being choked off somewhere. Pushing past the manufacturer’s maximum rated static pressure doesn't just hurt efficiency, it puts a ton of strain on the blower motor. Over time, this can lead to premature equipment failure and could even void your warranty.

Keeping an eye on these levels is a critical part of any good maintenance routine. In fact, our own HVAC preventative maintenance checklist highlights why these professional checks are so important for your system's long-term health.

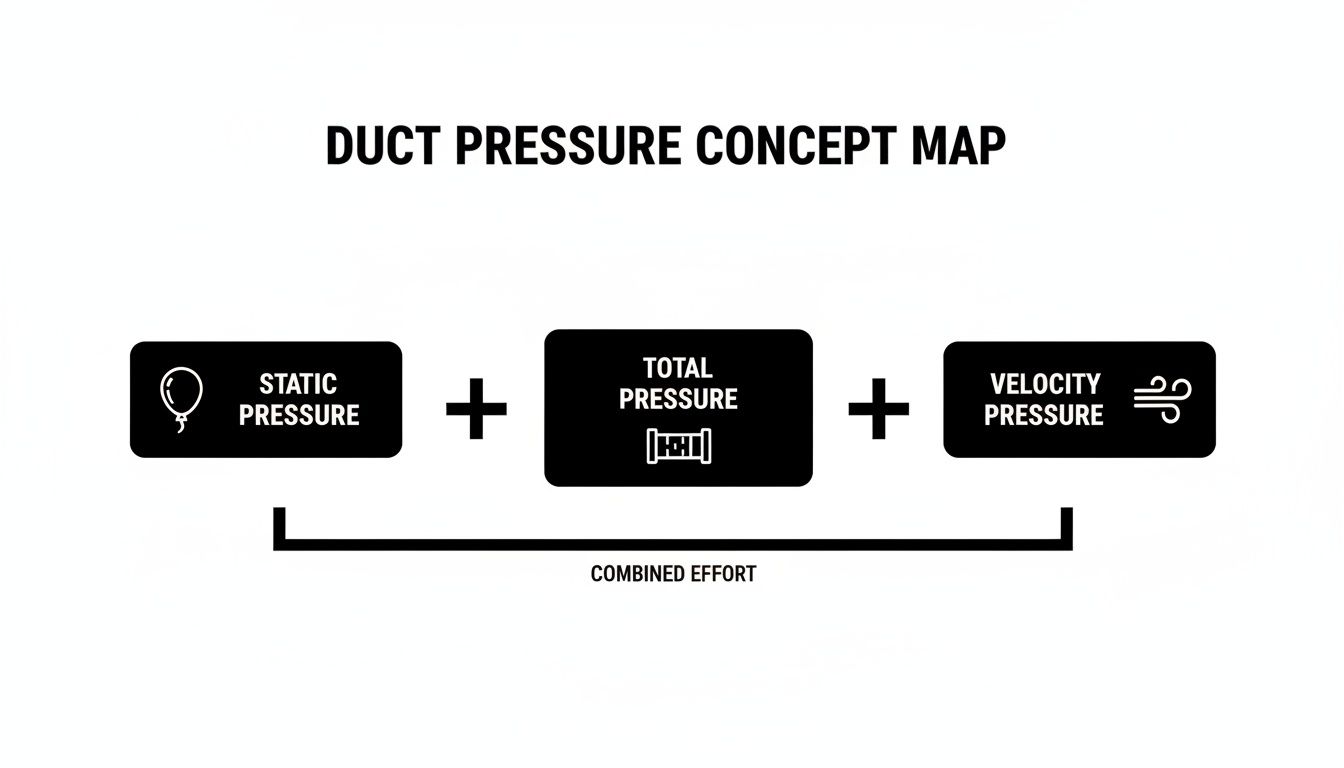

The concept map below shows how the different types of pressure inside your ducts all work together.

As you can see, the outward-pushing static pressure and the forward-moving velocity pressure combine to create the total pressure in the system. It's all a balancing act.

Identifying Problematic Pressure Levels

To give you a better feel for what a technician is looking for, here’s a quick breakdown of what different static pressure readings usually mean for your HVAC system.

You can think of a static pressure test as taking your HVAC system's blood pressure. A high reading is a direct warning sign that the system is overworked and its long-term health is at risk.

Below is a simple guide to help you understand what those numbers mean when you're talking with a professional about your system's performance.

Static Pressure Levels and System Health

This table breaks down static pressure readings (in inches of water column) into categories, explaining what each range means for your HVAC system's performance and health.

Static Pressure (in. WC) | Performance Level | Impact on System |

|---|---|---|

Below 0.5 | Optimal | The blower is running smoothly with little strain. Airflow is excellent, comfort is high, and the equipment should last a long time. |

0.5 - 0.8 | Acceptable but High | The system is definitely working harder than it should. This can lead to lower efficiency, some airflow issues, and more noise. |

Above 0.8 | Problematic | Here, the blower is severely strained. Expect big drops in airflow, high energy bills, loud operation, and a serious risk of motor failure. |

Understanding these levels helps you have a much more informed conversation with your HVAC pro about what's going on with your system and what it needs to get back on track.

The Real Cost of High Static pressure

High static pressure isn't just a number on a technician's gauge; it's a silent killer for your HVAC system that hits your comfort and your wallet hard. When your system is forced to fight against all that resistance, it sets off a chain reaction of problems you can often see, hear, and feel. In my experience, it's the hidden culprit behind many common HVAC complaints.

Imagine your system's blower motor is like a car engine stuck driving up a steep hill, 24/7. That constant strain forces the motor to work way harder just to circulate air, which translates directly into higher energy bills. It might not seem like much at first, but that extra effort adds up to a surprisingly bigger electricity bill over time.

Where Does This Extra Pressure Come From?

This suffocating resistance doesn't just materialize out of thin air. It’s caused by real, physical blockages that are literally choking the airflow in your HVAC system. Finding these common culprits is the very first step to relieving the pressure and getting your system back to peak health.

Here are the most frequent offenders I see in the field:

Clogged Air Filters: A dirty filter acts like a dam in your ductwork. This is, without a doubt, the #1 most common and easily fixed cause of high static pressure.

Dirty Evaporator Coils: Over time, the indoor coil can get caked with a thick blanket of dust and grime, making it incredibly difficult for air to pass through.

Restrictive or Undersized Ductwork: Ducts that are too small for the system, riddled with sharp turns, or were just poorly designed from the start create permanent bottlenecks.

Blocked Vents and Registers: It’s amazing how often I find furniture, rugs, or even curtains pushed up against supply or return vents. This effectively seals off parts of the system, trapping air and jacking up the pressure.

Knowing what to look for can help you figure out why your system always seems to be struggling.

Recognizing the Symptoms of an Overworked System

So, how can you tell if your HVAC system is wrestling with high static pressure? The signs are often brushed off as just weird quirks of the house, but they are classic red flags of an inefficient, overburdened system. You might notice that certain rooms, usually the ones farthest from the furnace or air handler, are perpetually too hot in the summer or too cold in the winter, no matter how you fiddle with the thermostat.

Another dead giveaway is weak or inconsistent airflow coming from your vents. You might also hear strange noises, like a high-pitched whistling or a low hum from the ductwork. That's literally the sound of air being squeezed through spaces that are too tight.

High static pressure in ductwork creates significant operational and financial consequences. When pressure is too high, the system's fan motors must work much harder to push air, leading directly to increased energy use and higher utility bills. The financial impact is serious, as systems with improper static pressure often face sky-high utility costs and premature component failure. To understand this further, discover more insights about why accurate pressure measurement is critical for HVAC efficiency from TSI Incorporated.

Ultimately, all this strain leads to more frequent breakdowns and a much shorter lifespan for your expensive equipment. The constant battle wears down the blower motor and can even fry the compressor, leading to some truly eye-watering repair bills. Learning some proven ways to lower your electric bill in 2025 can help ease the financial pain, but fixing the root cause is the only real long-term solution.

Practical Steps to Reduce Static Pressure

Here’s the good news: you can often make a real difference in your system's health and performance with a few straightforward checks. High static pressure frequently comes down to simple, fixable issues that don't always require an expert.

By taking these proactive steps, you can tackle the most common airflow restrictions head-on, easing the strain on your system and making your home more comfortable. Tackling these issues is also a great way to boost your system's efficiency. For a deeper dive, check out our guide on how to improve HVAC efficiency and lower energy bills.

Start With Simple System Checks

Before you start thinking about complex fixes, let's run through an easy DIY checklist. These common-sense steps are usually all it takes to find and fix the main culprits behind high what is static pressure in ductwork.

Check Your Air Filter: This is the number one cause of high static pressure, hands down. A dirty, clogged filter is like a roadblock for air, forcing the blower motor to work overtime just to pull air through. Make sure you're replacing it according to the manufacturer's guidelines, which is usually every 30 to 90 days.

Inspect All Vents and Registers: Take a walk around your house and eyeball every single supply and return vent. Are they all open? Is anything blocking them? Furniture, rugs, curtains, and even the dog's bed can create a major bottleneck if they're covering a vent.

Perform a Visual Duct Inspection: If you can safely access any of your ductwork in the attic, basement, or crawlspace, take a quick look. You're searching for obvious signs of trouble like crushed sections, sharp kinks that look unnatural, or joints that have come apart. Any of these can seriously restrict airflow.

Remember, every single obstruction, no matter how small it seems, adds to the total resistance your HVAC system has to fight against. Clearing these blockages is the quickest way to lower static pressure and get your airflow back on track.

Why Each Step Matters

It helps to understand why you're doing these things. Changing the air filter isn't just about breathing cleaner air; it's about letting your entire HVAC system "breathe" freely. Keeping a vent open isn't just for that one room's comfort; it's a critical release valve that keeps pressure from building up across the whole network.

This principle of preventing waste applies elsewhere, too. For those managing larger commercial spaces, it’s interesting to see how air curtains can lead to significant savings by controlling airflow at entryways. At home, these simple checks give your system the clear path it needs to run efficiently, saving you money and preventing early failure of expensive parts.

When You Need a Professional HVAC Technician

While swapping a dirty filter or unblocking a vent are simple fixes any homeowner can tackle, some static pressure problems are rooted much deeper in your HVAC system. Have you gone through all the basic checks and are still dealing with weak airflow, weird noises from the vents, or rooms that just won't get comfortable?

If so, it's time to call in a professional. Ignoring these persistent symptoms is a gamble that can lead to expensive, catastrophic equipment failure. An expert technician has the specialized tools and, more importantly, the experience to see past the obvious and pinpoint the real source of the trouble.

Advanced Solutions Only a Pro Can Provide

When the simple stuff doesn't cut it, a certified HVAC technician can perform advanced diagnostics and repairs that are out of reach for the average homeowner. Their expertise is absolutely critical for complex issues affecting what is static pressure in ductwork.

Here are a few things only a pro can safely and effectively handle:

Accurate Pressure Measurement: A technician uses a tool called a manometer to get precise static pressure readings. This isn't guesswork; it’s a data-driven test to see if your system is operating outside the manufacturer's safe limits.

Thorough Duct Cleaning: Forget a shop vac at the register. Professionals use high-powered, specialized equipment to scrub years of caked-on dust, construction debris, and other hidden obstructions from the entire length of your ductwork.

Blower Fan Speed Adjustment: It's possible your system's blower is working way too hard for your home's duct design. A technician can properly adjust the fan speed to match your system’s specific needs, which can drastically reduce pressure and noise.

Duct Sealing and Modification: Leaky ductwork is a huge energy waster and wreaks havoc on pressure balance. A pro can find and seal these leaks. In some cases, where the original installation was poorly designed, they might even need to modify sections of the ductwork to correct airflow problems.

A certified professional doesn't just treat the symptoms; they diagnose the underlying disease. Investing in an expert inspection protects your HVAC system, ensuring it runs safely and efficiently for years to come and safeguarding your significant home investment.

When you suspect a serious static pressure problem, making the call to a professional like Purified Air Duct Cleaning is the smartest and safest move you can make.

Frequently Asked Questions About Static Pressure

To wrap up our discussion on what is static pressure in ductwork, let’s tackle some of the most common questions homeowners ask. These quick answers will help reinforce the key concepts and give you a fast reference guide for practical situations.

Is Low Static Pressure a Problem?

Yes, it certainly can be. While high pressure from restrictions is the more common villain, extremely low static pressure is often a major red flag. It usually points to significant leaks in your ductwork, where all that conditioned air you're paying for is escaping into your attic or crawlspace instead of reaching your rooms.

This not only wastes a tremendous amount of energy but can also pull dust, insulation fibers, and other contaminants into your airstream, wrecking your indoor air quality. A professional can perform a duct leakage test to find and seal these costly gaps for good.

How Often Should I Check My Static Pressure?

It’s an excellent practice to have your system’s static pressure tested during your annual HVAC maintenance appointment. Any qualified technician worth their salt should include this measurement as part of a thorough system inspection to ensure everything is running within the manufacturer’s specifications.

You should also request a test if you notice any persistent signs of poor airflow, right after you’ve installed a brand-new HVAC system, or following any major home renovations that might have altered your home’s layout and airflow dynamics.

Remember, a static pressure reading is a vital health metric for your HVAC system. Regular checks can catch problems early, preventing expensive damage and ensuring your equipment operates efficiently for its entire expected lifespan.

Will a High-MERV Filter Increase Static Pressure?

Yes, it absolutely will. High-MERV and HEPA filters are designed with a much denser weave to capture smaller airborne particles like pollen and mold spores. While this is great for improving air quality, that dense material creates more resistance for air to pass through, which directly increases static pressure.

The catch is, not all HVAC systems are built to handle this extra workload. Using a filter that’s too restrictive for your specific unit can strain the blower motor, choke off airflow, and lead to premature failure. Always check your HVAC system’s manual or consult a professional to find out the maximum MERV rating your system can safely support without causing bigger problems.

If you're experiencing signs of high or low static pressure and the simple fixes aren't working, it’s time to call in the experts. Purified Air Duct Cleaning provides professional diagnostics and solutions to restore your HVAC system’s health and efficiency. Contact us today for a free quote and breathe easier knowing your system is in good hands.