A Homeowner's Guide to Dryer Vent Code Requirements

- shawnpurifiedair

- Dec 14, 2025

- 15 min read

Dryer vent code requirements aren't just bureaucratic red tape; they are strict rules put in place to prevent house fires and even carbon monoxide poisoning. These regulations get specific about the materials, length, and termination points for your dryer’s exhaust system to keep it running safely. Ignoring them can create some seriously dangerous, even life-threatening, hazards in your home.

Why Dryer Vent Codes Are Not Just Rules But Lifesavers

Staring at a building code can feel a little intimidating, but these aren't just arbitrary rules pulled out of thin air. They are critical safeguards that directly address very real risks. Improper venting is a top cause of appliance-related home fires, and for gas dryers, it can lead to a dangerous buildup of carbon monoxide.

To really get why these codes matter, it helps to start by understanding the core principles of building codes. This background knowledge makes it crystal clear why such specific rules exist for an everyday appliance like a clothes dryer.

The Anatomy of a Dryer Vent Hazard

Think of your dryer vent like a critical artery for your home. When it’s installed correctly and kept clear, it does its job perfectly: pushing hot, moist, lint-filled air safely outside. But when that vent gets clogged, crushed, or is made from the wrong materials, it’s like a blocked artery.

This restriction forces your dryer to work way harder and get much hotter. The trapped lint, which is incredibly flammable, starts to pile up right next to the dryer’s heating element. It's a perfect storm for a fire. You can dive deeper into the specific causes of dryer fires in our detailed guide.

Codes Backed by Hard Data

The rules you see in building codes aren't just guesswork; they're direct responses to real-life tragedies. For instance, the International Residential Code (IRC) sets the maximum length for a dryer vent at 35 feet, and that number gets smaller with every bend in the pipe.

These standards come from years of fire safety data. The National Fire Protection Agency (NFPA) once reported a staggering 13,775 house fires caused by dryers in a single year. These incidents led to 418 injuries, 15 deaths, and $196 million in property damage, driving home just how critical compliance is.

This data is precisely why following dryer vent code requirements is so non-negotiable. These rules get into the nitty-gritty, demanding things like:

Proper Materials: Using smooth-walled metal ducts is a must. Flimsy and flammable plastic or foil ducts are a major fire hazard.

Secure Connections: Joints have to be sealed with metal tape. Screws are a big no-no because they stick out into the duct and snag lint.

Correct Termination: The vent cap on the outside of your house can't have a screen, which is notorious for trapping lint and creating a blockage.

At the end of the day, these codes turn your dryer vent from a simple tube into a key part of your home’s safety system. Following them is the single best thing you can do to protect your property and, more importantly, your family.

Choosing the Right Materials for Your Dryer Vent

When it comes to a safe, code-compliant dryer vent installation, the single most important decision you'll make is choosing the right duct material. This isn't just a friendly suggestion; it's a critical safety rule designed to prevent fires and keep your dryer running like it should. The whole point of these codes is to give hot air and lint the smoothest, most direct escape route from your home.

Think of a proper dryer vent like a waterslide. Codes today demand smooth-walled rigid or semi-rigid metal ducts because they create a slick, clear path. Lint and hot, damp air just glide right out of your house, no fuss, no muss.

Using the wrong stuff is like trading that waterslide for a bumpy, winding dirt road. It’s a recipe for trouble.

Why Some Materials Are Prohibited

It surprises a lot of homeowners to learn that those flexible, white plastic or foil accordion-style hoses you see in big-box stores are actually a massive fire hazard. There's a good reason most building codes have banned them.

Here’s why they’re so dangerous:

They're flammable: Lint is incredibly easy to ignite. If a spark catches inside a plastic or foil duct, the duct itself adds fuel to the fire, helping it spread in a flash.

They trap lint: The accordion-like ridges create thousands of tiny nooks and crannies where lint gets snagged, quickly leading to a serious blockage.

They crush easily: These flimsy hoses get kinked or squashed behind the dryer in a heartbeat. That chokes off the airflow, causing the dryer to overheat and creating a dangerous fire risk.

Using these forbidden materials is one of the most common violations of dryer vent code requirements we see, and it’s a leading cause of dryer-related house fires. For a full picture of what a correct setup looks like, take a look at our guide on proper clothes dryer venting made simple.

Identifying Code-Compliant Ducting Materials

To make sure your installation is safe and up to snuff, you have to use materials that are specifically approved for dryer venting. These are built for durability, heat resistance, and maximum airflow.

Let's break down the good, the bad, and the ugly of dryer vent materials.

Approved vs Prohibited Dryer Vent Materials

This table shows you exactly what's allowed and what's not, and more importantly, why. Sticking to the "Approved" column is the first step toward a safe system.

Material Type | Description | Code Compliant? | Primary Risk if Used Incorrectly |

|---|---|---|---|

Rigid Metal Duct | Smooth-walled aluminum or galvanized steel duct. Offers the best airflow and durability. | Yes (Required) | Improper sealing at joints can cause leaks. |

Semi-Rigid Metal Duct | A flexible metal duct with a smooth interior. Good for transition connections. | Yes (Limited Use) | Can be crushed if not installed carefully. |

Foil Accordion Duct | A flimsy, ribbed duct made of thin foil. Easily crushed and traps lint. | No (Prohibited) | High fire risk due to flammability and blockages. |

Plastic/Vinyl Duct | A flexible white plastic hose, often with a ribbed design. | No (Prohibited) | Extremely flammable and prone to kinking. |

As you can see, the only real players in the game are rigid and semi-rigid metal. This isn't an arbitrary rule; building codes have evolved based on hard safety data. Since the early 2000s, codes like the International Residential Code (IRC) Section M1502 now require rigid metal ducts at least 0.016 inches thick with smooth interiors. This change happened after extensive research showed a direct link between duct material, fire risk, and appliance efficiency.

Important Takeaway: Modern building codes only approve rigid or semi-rigid metal ducts for dryer venting. Always look for products that are UL 2158A-listed for clothes dryer transition use to be sure you're getting the right stuff.

Starting with the right materials is the single most effective thing you can do for a safe and efficient dryer vent system. It cuts off the main cause of lint buildup at the source and dramatically lowers the risk of a devastating fire.

Calculating Vent Length and Proper Termination

Beyond the duct material itself, two of the most common spots where dryer vent systems fail are the total length of the run and where it exits your home. Getting these details right is a massive part of meeting dryer vent code requirements and keeping your system safe. A vent that's too long or ends improperly creates the same dangerous blockages as using the wrong pipe.

Think of the hot air pushing out from your dryer like a runner trying to finish a race. A short, straight path is an easy sprint. But every bend and extra foot of duct adds to the distance, exhausting the "runner" before it can get all that hot, moist, lint-filled air safely outside.

Demystifying the Maximum Length Rule

Most building codes, including the International Residential Code (IRC), cap the maximum developed length of a dryer vent at 35 feet. But hold on, this isn't as simple as pulling out a tape measure. You have to calculate the equivalent length, which is a fancy way of saying you must account for the friction and resistance that every single turn adds to the system.

The formula is straightforward but absolutely crucial. You start with the straight-pipe measurement and then add a penalty for each elbow.

For every 90-degree bend: Add 5 feet to your total length.

For every 45-degree bend: Add 2.5 feet to your total length.

Let's walk through a common scenario. Say your vent run has 15 feet of straight pipe, but it needs two sharp 90-degree turns to get around some plumbing. The math would be: 15 feet (straight pipe) + 5 feet (first 90° bend) + 5 feet (second 90° bend) = 25 feet of equivalent length. This is well within the 35-foot limit and perfectly code-compliant.

Mastering Proper Vent Termination

The termination point, where the vent actually exits your home, is just as critical as the duct run itself. The wrong vent cap can completely sabotage an otherwise perfect installation, creating a serious fire risk right at the wall. A proper termination has to let air out freely while keeping pests and bad weather from getting in.

Here's the big rule: the termination cap must not have a screen. It might seem like a good idea for keeping critters out, but those screens clog up with lint incredibly fast. This creates a dam, trapping flammable debris and forcing heat to back up all the way to the dryer.

Instead, codes require a termination fitting with a damper. This is just a little flap that the force of the dryer's exhaust pushes open. When the dryer shuts off, it closes on its own, blocking pests without ever getting in the way of airflow.

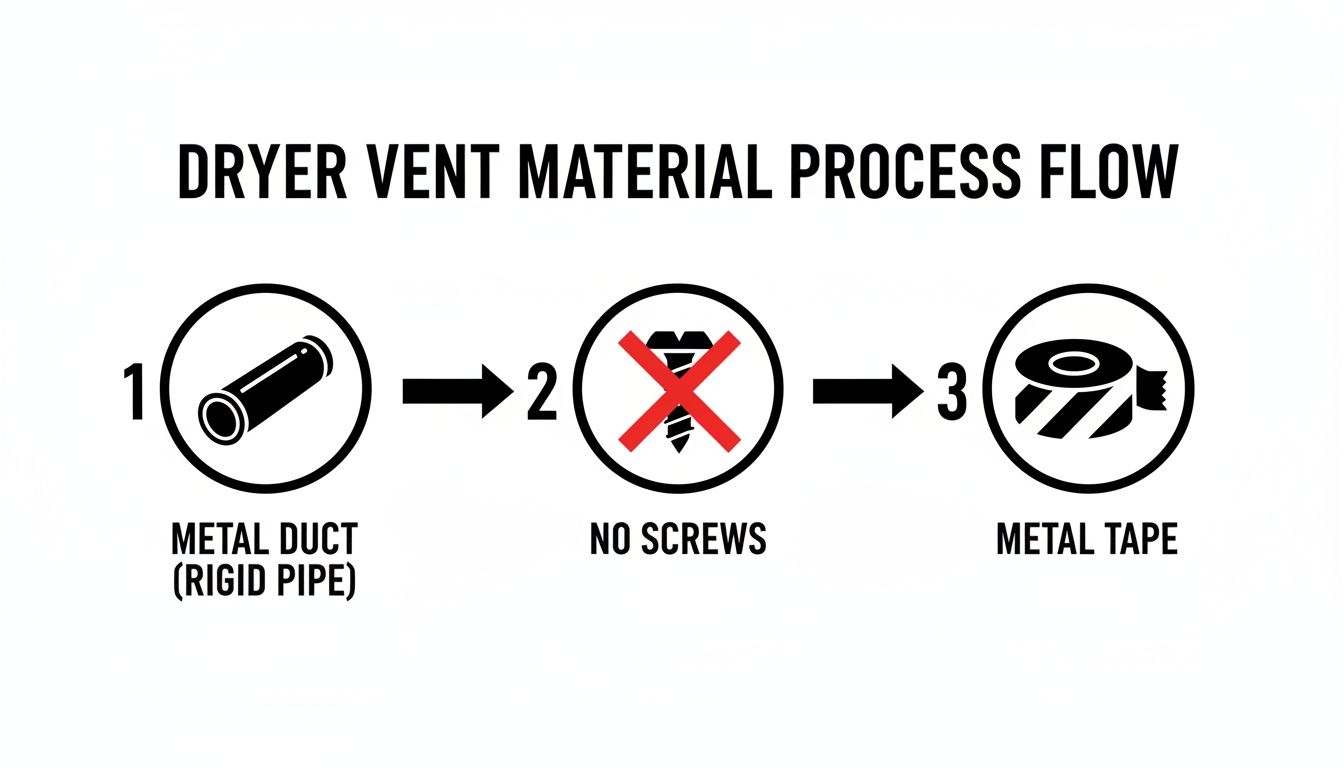

This diagram breaks down the essential parts of a safe dryer vent system from start to finish.

You can see the logical flow, starting with the right metal ducting, moving to secure connections without screws, and finishing with a proper seal using metal tape. These are the core principles for a safe setup.

On top of the cap design, codes also spell out clearance rules. The vent needs to terminate a safe distance from windows, doors, and air intakes to make sure you're not just sucking all that moist, linty air right back into your house. If you want a deeper dive into designing the whole system, check out our guide on safe and efficient clothes dryer venting.

Typical clearance rules you’ll see include:

At least 3 feet away from any door or window.

At least 3 feet away from any air conditioning unit or other air intake.

At least 1 foot above the ground to avoid getting blocked by snow, mulch, or plants.

By carefully calculating your vent’s equivalent length and making sure the termination point is up to code, you’ve already handled two of the most critical safety factors for your entire dryer system.

Handling Gas Dryers and Concealed Installations

While most dryer vent setups are pretty straightforward, some installations raise the stakes significantly. We’re talking about gas dryers and vents that are hidden inside walls or ceilings. These situations demand an even stricter approach to dryer vent code requirements, because a small mistake isn't just a fire hazard; it could introduce deadly gases into your home.

Getting these complex jobs right is non-negotiable for safety. The rules get tougher because the potential consequences, like carbon monoxide poisoning, are so much more severe. If you're dealing with either of these setups, you absolutely need to know these specific codes.

Special Rules for Gas Dryer Venting

Gas dryers introduce a whole new level of risk. Their exhaust isn't just lint and hot, moist air; it also contains carbon monoxide, a silent killer that's both colorless and odorless. A leak in the vent system of a gas dryer isn't just a fire risk; it can quietly fill your living space with poison.

This is exactly why building codes are so rigid about gas dryer vents. Every section of the duct must be made of rigid metal, and every single joint has to be sealed completely airtight with approved foil tape. You can dive deeper into the dangers of bad venting and learn if dryer exhaust is harmful in our detailed article.

The number one goal for gas dryer venting is zero leakage. A perfectly sealed metal duct system ensures that 100% of combustion byproducts, including carbon monoxide, are pushed safely outside, protecting your family from an invisible threat.

Navigating Concealed Dryer Vents

What happens when a dryer vent runs through a hidden space like a wall, floor, or ceiling? It becomes impossible to check for lint buildup or damage without ripping out drywall. Because you can't see it, the installation has to be perfect from day one.

The most critical rule for concealed vents is the absolute ban on using screws to connect duct sections. Screws poke into the duct's interior, creating little hooks that snag lint. These snags are the starting point for a major clog, which can choke off airflow and cause the dryer to overheat.

Instead of screws, the code demands a much cleaner approach for concealed ducts:

Secure Connections: All joints must be connected using methods that leave the inside of the pipe completely smooth. This usually involves mechanical fasteners that clamp from the outside.

Mandatory Sealing: Every seam and joint has to be meticulously sealed with code-approved metal foil tape. This prevents lint and moisture from escaping into your wall cavity, where they can cause mold and other damage.

Rigid Metal Only: Only solid, rigid metal ducts are allowed in concealed spaces. Flexible or semi-rigid ducts are forbidden because they can be easily crushed, kinked, or damaged during construction.

Following these strict rules ensures that a vent you can't see remains a safe, clear pathway for years to come. With concealed vents, getting it right the first time is the only option, as going back to fix it is a messy and expensive job. By following these specific dryer vent code requirements, you ensure even the most complicated installations are both safe and built to last.

How Global Standards Influence Your Local Codes

It’s easy to think the rules for your dryer vent are just some local ordinance, but they're actually part of a much bigger picture, one that connects your home to a global network of safety standards. Think of it like a ripple effect. An international body like the International Code Council (ICC) develops a baseline model, and those recommendations trickle down, shaping national, state, and finally, your city’s specific codes.

This worldwide conversation is constantly pushing manufacturers to build safer, more efficient appliances. So, when you follow your local dryer vent code requirements, you’re not just checking a box for a permit; you're plugging into a global commitment to higher safety benchmarks for everyone.

The Global Push for Safer Homes

These international standards don’t just appear out of thin air. They’re the result of pooling safety data, research, and new technology from all over the world. A new sustainability trend in Europe might inspire codes focused on energy efficiency, while smart-home tech developed in North America could lead to standards for automated safety sensors.

This collaborative spirit is a huge win for consumer safety. For instance, understanding a national framework like the Building Code of Australia (BCA) helps clarify why certain local rules exist, ensuring your installation meets standards that are recognized across the industry. It’s proof that home safety is a shared global value, not just a local concern.

This interconnectedness also has a massive economic footprint. Strict dryer vent code requirements have fueled major growth in the global market, pushing the dryer vent duct sector toward a valuation of $1,262.3 million in 2025. This surge is driven by mandates for energy-efficient ventilation and routine maintenance in key markets. In the US alone, where 82% of people now see IoT-based overheating sensors as vital, regulations like the 2021 IRC demand smooth metal ducts to help prevent the 15,000+ dryer fires reported each year in North America.

How International Codes Reach Your Home

So how does a global safety idea become the rule you have to follow in your own home? The process is pretty straightforward, designed to make sure best practices are adopted everywhere.

Model Codes Are Created: Big organizations like the ICC create "model codes" based on tons of research and expert opinions.

National Adoption: Countries take these model codes and adopt them, sometimes tweaking them to fit their specific needs.

State and Local Amendments: States and cities then adopt the national code, often adding their own rules to address local climate, common building practices, or specific safety priorities.

This layered system ensures that while the core safety principles are consistent worldwide, the exact rules you follow are tailored perfectly for your area. It’s a framework built for both universal safety and local relevance.

Seeing it this way changes everything. Compliance stops being a chore and becomes a meaningful action. By sticking to these codes, you’re making sure your home meets a safety standard that’s recognized and respected across the globe. This also ties directly into overall home wellness, something you can explore further in our guide to indoor environmental quality standards.

Spotting and Fixing Common Code Violations

Knowing the rules is one thing, but spotting a problem in your own laundry room is a whole different ballgame. The good news is that many of the most common breaches of dryer vent code requirements are surprisingly easy to see if you just know what to look for. Think of this section as your personal inspection checklist.

Once you can recognize these mistakes, you can take action. These fixes don't just get your home up to code; they also dramatically cut down on fire risks and help your dryer run a whole lot better. Let's walk through the issues we see most often and what to do about them.

Prohibited Venting Materials

One of the scariest and most frequent violations is the use of the wrong kind of ducting. Just take a peek behind your dryer. If you see a white plastic, vinyl, or flimsy foil accordion-style hose, you have a problem. These materials are a serious fire hazard because they're flammable, the ridges trap lint like crazy, and they crush under the slightest pressure.

The Problem: These materials are banned by almost every modern building code for a reason. According to the U.S. Fire Administration, failure to clean is the top cause of the 2,900+ home fires started by dryers each year, and those flimsy, lint-trapping ducts make a thorough cleaning next to impossible.

The Fix: This one's urgent. Immediately replace any plastic, vinyl, or foil duct with a rigid or semi-rigid metal duct. The smooth interior is key: it's durable, resists getting crushed, and lets lint flow right through.

Excessively Long or Complicated Duct Runs

Another all-too-common issue is a vent path that's just too long. The magic number is typically 35 feet of equivalent length. And remember, every sharp 90-degree turn adds 5 feet to your total, while a 45-degree bend tacks on 2.5 feet. A run that's too long essentially chokes the airflow, causing lint to back up.

The first thing to try is rerouting the duct for a shorter, straighter shot to the outside. If that’s simply not possible, the code does allow for a listed and labeled dryer booster fan to be installed to keep the air moving properly.

It's amazing how many problems are caused by one simple mistake: pushing the dryer too far back against the wall. This crushes the transition duct, creating a major blockage. That single action can create an immediate fire hazard, no matter what the duct is made of or how short it is.

Improper Exterior Terminations

That little vent cap on the outside of your house is a critical safety checkpoint. A lot of homeowners install caps with screens thinking they’ll keep pests out, but this is a direct violation of dryer vent code requirements. Why? Because those screens get clogged with lint in no time, creating a dangerous and flammable blockage.

A code-compliant vent cap should have a damper that flaps open when the dryer is on and closes when it's off. Also, be wary of roof vents. Many are designed for bathroom fans, not dryers, and will clog up just as fast as a screened cap. You need a termination specifically designed for the high airflow and lint of a dryer.

Here’s a quick checklist you can use to spot and fix these common issues:

Check Your Duct: Is it plastic, vinyl, or that crinkly foil? If yes, it has to go. Swap it for smooth-walled metal.

Inspect the Connection: Gently pull your dryer away from the wall. Is the duct squashed or kinked? Straighten it out and give it some breathing room.

Examine the Vent Cap: Head outside and take a good look at the vent termination. If you see a screen, remove it immediately. Replace the whole cap with a proper, damper-style version made for dryers.

Frequently Asked Questions About Dryer Vent Codes

Even when you have a good handle on the rules, some situations can still leave you scratching your head. Let's tackle some of the most common questions and myths we run into out in the field.

Can I Use a Screen on My Vent Cap to Keep Pests Out?

This is a big one, and the answer is a hard no. Dryer vent codes are very clear: screens are prohibited on the exterior termination cap. It seems like a smart idea for keeping critters out, but that screen will clog up with lint in no time.

Once it's clogged, airflow is choked off. This forces your dryer to work harder, overheat, and creates a massive fire hazard. Instead, the code requires a termination fitting that has a backdraft damper, a flap that wind from the dryer pushes open, and that closes on its own when the cycle ends. It's a simple, effective design that deters pests without ever blocking the exhaust.

What Should I Do If My Vent Run Is Longer Than 35 Feet?

So you've measured your vent path and it's longer than the standard 35-foot maximum. What now? Your first move should be to look for a shorter, more direct route to the outside. Sometimes a small rerouting can solve the whole problem.

If a shorter path just isn't in the cards, the code does allow for a listed and labeled dryer booster fan. These are specifically designed to keep the air moving properly over those longer distances. Be warned, though: you have to follow the manufacturer's installation instructions to the letter. Putting it in the wrong spot can make it useless or even dangerous. This is one of those times where calling a professional is your best bet.

How Do I Find the Specific Code for My City or State?

Building codes can feel like a moving target because they change from one town to the next. While most places base their rules on model codes like the International Residential Code (IRC), they almost always have their own local amendments.

The only surefire way to know the exact rules for your property is to get in touch with your local building department or code enforcement office. You can often find the information on their website, but a quick phone call can clear up any confusion.

For guaranteed compliance, hiring a licensed HVAC contractor or a certified dryer exhaust technician is the safest choice. Professionals are required to stay current on all local codes and amendments, ensuring your installation is done right the first time.

This takes all the guesswork out of the equation and protects your home from the very real fire and safety risks these rules are designed to prevent. Following the correct dryer vent code requirements is a small effort that pays off big in peace of mind.

A clean and compliant dryer vent system is essential for your family's safety and your home's efficiency. If you have any doubts about your current setup or need a professional inspection, the certified technicians at Purified Air Duct Cleaning are here to help. We ensure your system meets all local codes, reduces fire risk, and operates at peak performance. Visit us at https://www.purifiedairductcleaning.com to schedule your free quote today.